OVERTURNING CONTAINER MIXER type TRR

This makes the TRR Bonding mixer a secure and reliable solution for high-quality powder coating production, combining consistent results with maximum operator and plant safety. It is designed following ATEX directives.

Size from 300 to 1000 lts.

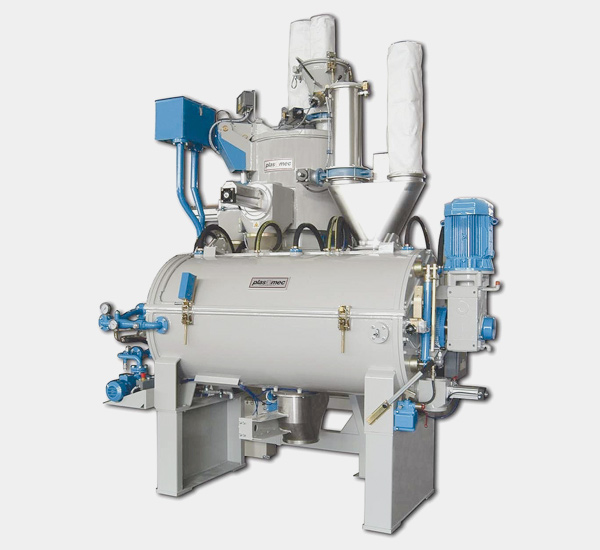

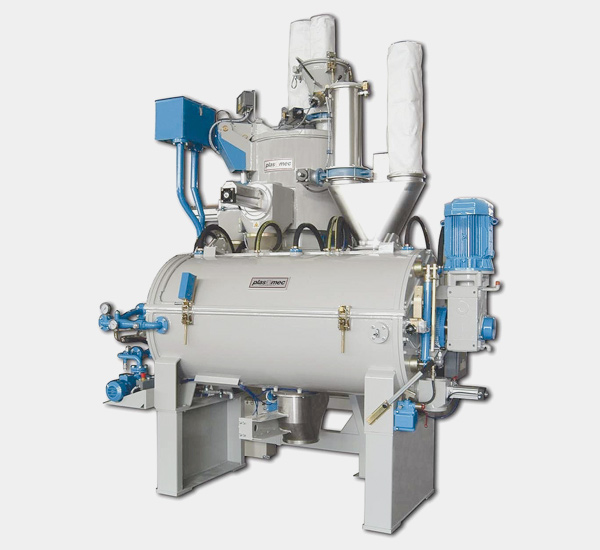

MIXING SYSTEM type COMBIBOND HC/B

The Mixing System COMBIMIX-HC/B in the Bonding version is a dedicated system for the safe and efficient incorporation of metallic pigments into powder coatings. Combining the high-speed mixing action of the TRM with the intensive cooling capacity of the HEC or, for small sizes, with vertical cooler RFV. It ensures controlled bonding of metallic pigments onto resin particles while controlling accurately the process temperature and preventing overheating and dust-related hazards. Equipped with an oxygen monitoring and control system, the COMBIMIX-HC Bonding version minimizes explosion risks and guarantees a secure process. The result is a consistent, high-quality bonded powder with maximum operator and plant safety. It is designed following ATEX directives.

Size from 50 lts TRM mixer with 100 lts RFV cooler up to 1200 lts TRM mixer with 3500 lts HEC cooler.

LABORATORY MIXER type TRL/B

The laboratory mixer TRL configurated for bonding process with all the necessary controls and safeties like oxygen control. Allows to find the proper mixing process conditions to be applied to the production mixing line.

to test the products. It is designed following ATEX directives.

Size from 5 to 20 lts.