HORIZONTAL BLENDER type MO

Horizontal mixers MO for plastic powders and granules are designed to provide intensive and uniform blending of bulk materials, additives, and regrind. Without a cooling jacket, they are particularly suitable where heating of the material is not a concern, such as in

specific applications with thermosetting materials. Their robust construction and efficient mixing process ensure consistent homogenization, high reliability, and excellent preparation for downstream operations or final packaging.

Size from 500 to 23000 lts.

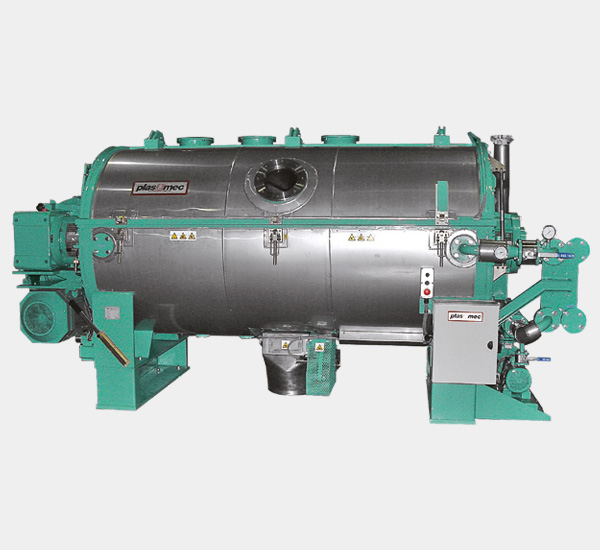

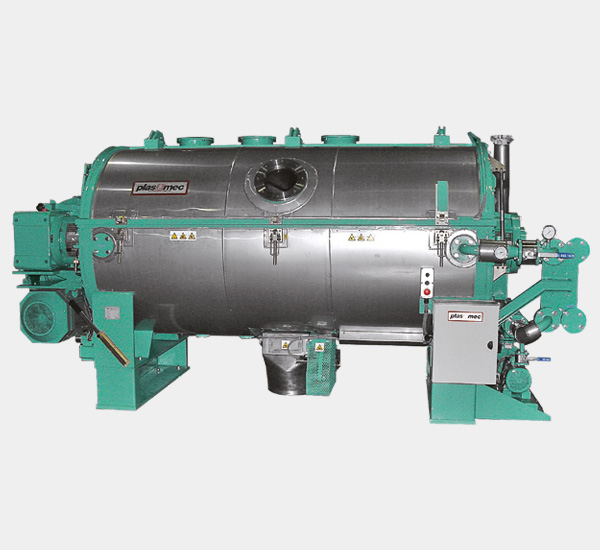

HORIZONTAL MIXER type HUM

Horizontal mixers HUM with double jacket for water cooling are designed to combine intensive and uniform blending with effective temperature control. The cooling system prevents material overheating, making them ideal for applications where thermal stability is essential, such as in the processing of thermoplastic powders or heat-sensitive formulations. Robust and efficient, they ensure consistent homogenization, high reliability, and optimal preparation for downstream operations or final packaging.

Size from 1500 to 7500 lts.

HORIZONTAL HEATED BLENDER type HEB

The horizontal blender HEB has been specifically designed for processes that require gentle thermal treatment. Its vessel is equipped with a double jacket for the circulation of hot water or diathermic oil, and is externally insulated to ensure efficient heat transfer and energy savings.

Unlike high-intensity mixers, the HEB operates with a slower process, making it particularly suitable for materials that cannot withstand high thermal stress while still ensuring homogeneous blending under controlled temperature conditions.

Size from 1500 to 4500 lts.